Likarolo tse tloahelehileng tsa tšepe

Ho chesoa ka tšepeke ntho e entsoeng (fabrication welding) kapa mokhoa o betliloeng oa ho kopanya litšepe.Nakong ea ts'ebetso ea welding, karolo ea mosebetsi le solder lia qhibiliha kapa li se ke tsa qhibiliha ho theha motsoako o tobileng.metalweldingpbonono.Nakong ea ts'ebetso ena, hangata khatello e boetse e hlokeha ho kenya letsoho ho cheselletsa.Ho na le mekhoa e fetang 40 ea litšepe, tse arotsoeng haholo ka mekhahlelo e meraro: tšubuhlellano ea fusion, welding ea khatello le brazing:

Fusion welding ke mokhoa oo sehokelo sa sekhechana sa mosebetsi se futhumatsoang ho fihlela boemo bo qhibilihisitsoeng nakong ea ts'ebetso ea welding mme welding e phethoa ntle le khatello.

Khatello ea ho cheseletsa ke ho etsa hore likarolo tse peli tsa mosebetsi li hlokomele ho tlamahana ha interatomic sebakeng se tiileng tlas'a khatello, e tsejoang hape e le solid-state welding.

Brazing ke ho sebelisa thepa ea tšepe e nang le ntlha e tlaase ea ho qhibiliha ho feta karolo ea mosebetsi e le solder, futhumatsa karolo ea mosebetsi le solder ho mocheso o phahameng ho feta sebaka sa ho qhibiliha sa solder le ka tlaase ho feta ntlha ea ho qhibiliha ha karolo ea mosebetsi. metsi solder ho kolobisa sengoathoana mosebetsi, tlatsa lekhalo segokanyimmediamentsi sa sebolokigolo le ho finyella Inter-diffusion pakeng tsa liathomo, e le ho hlokomela mokhoa tjheseletsa.

-

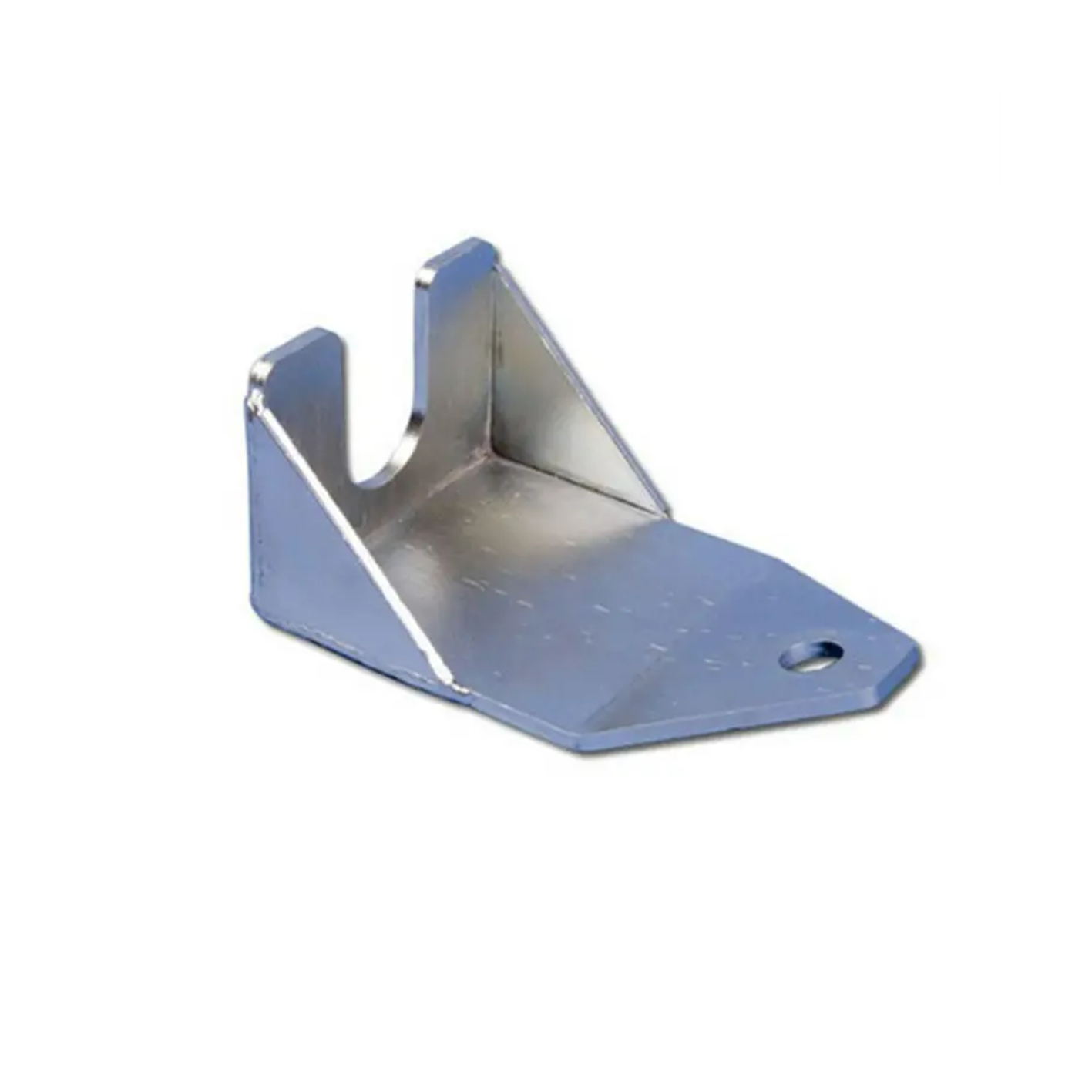

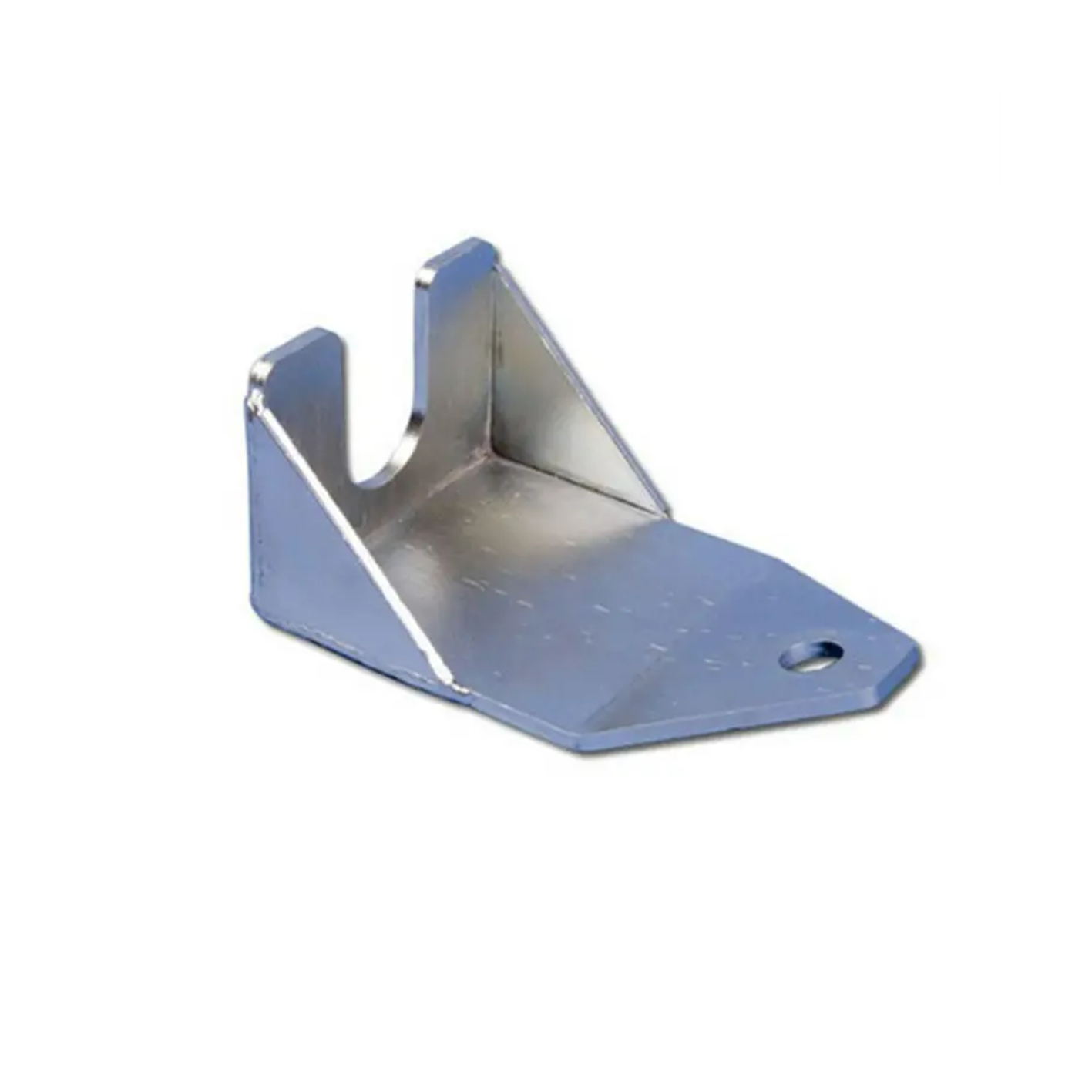

Customized tšepe lakane bended tjheseletsa boenjiniere mechine e likarolo tse ling

-

Tloaelo e phahameng matla a tšepe ea tšepe e entsoeng ka setempe

-

Customized tšepe kobang le tjheseletsa likarolo fektheri

-

Likarolo tse Welded tsa tšepe tse Tloaelehileng bakeng sa Terekere

-

Feme ea likarolo tsa Custom Sheet Metal welding

-

Likarolo tsa tšepe tse matla tse phahameng tse sebelisoang mererong ea kaho

-

OEM Carbon Steel Sheet Metal welding Parts Factory

-

Laser Cut Sheet Weldments bakeng sa Door And Window Accessories

-

Carbon Steel Sheet Metal Forming Stamping Bending Parts Welding

-

Mechini ea Temo Likarolo tsa Terekere Likarolo tse Welded

-

tšepe tšepe stamping le tjheseletsa likarolo ODM moetsi

-

OEM carbon tšepe kobang setempe dikopano bakeng sa likarolo tse ling serapeng